Offshore wind farms could do far more than just make clean power

With a few add-ons, wind farms could make green hydrogen and capture carbon dioxide, too

Offshore wind energy is more expensive than other renewables. One way to help these turbines pay off is to give them extra tasks. These jobs could include making hydrogen and capturing carbon dioxide from the air.

Peter Adams/Stone/Getty Images Plus

Share this:

- Share via email (Opens in new window) Email

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Share to Google Classroom (Opens in new window) Google Classroom

- Click to print (Opens in new window) Print

This is another in our series of stories identifying new technologies and actions that can slow climate change, reduce its impacts or help communities cope with a rapidly changing world.

Wind turbines provide a clean source of electricity. They work especially well out in coastal waters, where strong ocean breezes can spin their blades fast. These offshore wind farms cost more to build than onshore ones. But once installed, offshore wind could pick up bonus tasks that would boost the farms’ value.

Researchers in Canada think one of the best add-ons to wind farms is making hydrogen gas (H2). Each molecule of H2 consists of two hydrogen atoms bonded together. When burned or converted to electricity, the only byproduct is water. But H2 rarely occurs in nature. So to get this clean power source, people have to make it — often through some very dirty processes. The cleanest way to make H2 would be using energy from the wind or sun. Engineers refer to this as green hydrogen.

Hydrogen “is a clean-burning fuel and can also carry and store energy,” notes Haris Ishaq. He’s a mechanical engineer in at the University of Victoria in Canada. “Green hydrogen can solve many of today’s problems.”

His is not the first team to suggest making green hydrogen with offshore wind. Another team looked into it last year. Ishaq’s group now proposes adding a third task to wind farms to give them even greater value. These farms could also grab CO2 from the atmosphere through a process called “direct air capture,” or DAC.

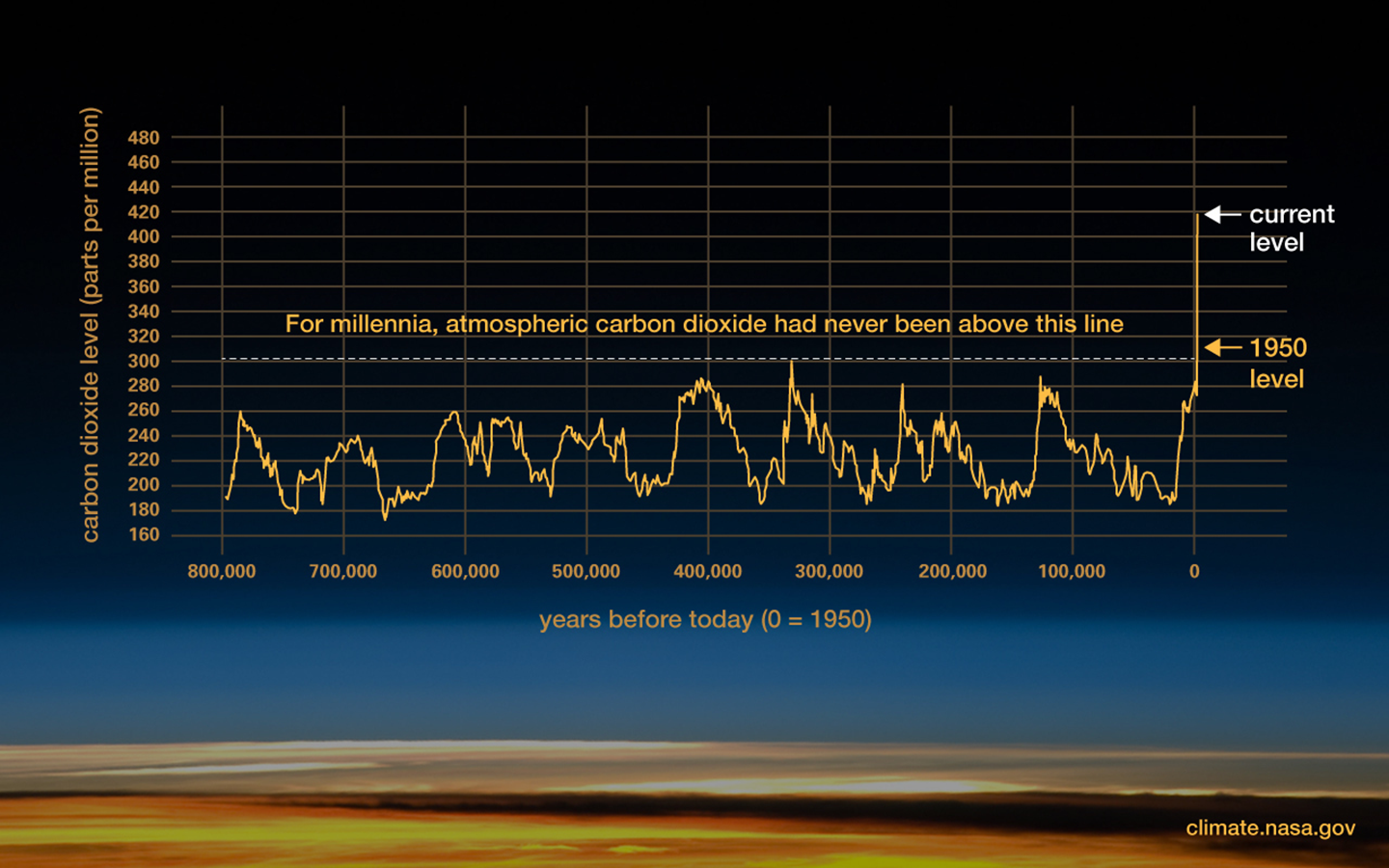

DAC has received a lot of attention as a new way to help limit climate change. The Canadian team described the merit of wind farms that offer these three services on July 16 in the International Journal of Hydrogen Energy.

Combining wind and water resources

With its mainland and the edges of its many islands, Canada has by far the world’s longest coastline — 243,042 kilometers (151,019 miles). Most of that land borders the Arctic Ocean. But more than 27,000 kilometers (16,800 miles) flank the Pacific. Canada has already installed many wind farms on its Pacific coast. These receive strong, steady breezes. And that’s not their only advantage. At sea, there’s also less competition than on land for the space they need.

But there are downsides to making wind power offshore. “It easily costs two to three times more than its onshore equivalent,” says Michiel Zaaijer. Why? Offshore equipment must be heavier than onshore equipment. It has to stand up to potential gale-force winds, big waves and strong currents. And sending people to install, operate and repair equipment at sea is costly, Zaaijer notes. He’s a wind-energy researcher at Delft University of Technology in the Netherlands. He also was part of the team that suggested adding green hydrogen to offshore wind last year.

Once a wind farm is in place, however, the water around it could be used to make another type of energy. A device called an electrolyzer can split some of that water into H2 and oxygen. (This is called hydrolysis. It’s the opposite of what happens in a hydrogen fuel cell, which makes water and electricity.)

One catch: The electrolyzer needs fresh water, not salt water. To remove the sea salt, Ishaq’s team now proposes removing the salt through reverse osmosis. This process uses an electric pump to force sea water through a salt-filtering membrane.

H2 made by the electrolyzer can become a raw ingredient for ammonia, which is used as fertilizer and in fuels. Or pipelines can send H2 to onshore storage facilities. When needed, gas turbines could convert its chemical energy into clean electricity for the power grid. (This grid-balancing role is important when wind and the sun don’t supply enough power. It’s a large-scale version of what batteries do and could provide electricity as needed to homes and businesses.)

“Underwater H2 pipelines use cheaper materials than electric cables,” Zaaijer says. “They can also transport 20 times more energy.” Making electricity and multipurpose H2, he argues, could help offshore wind farms provide more value.

Powering carbon-capture tech

For wind farms’ second bonus task — capturing carbon from the air — the researchers looked to existing DAC systems. Climeworks, a Swiss company, is one of the companies that makes them.

Their DAC devices resemble large vacuum cleaners and need electricity to run. Fans move air across a solid material that grabs CO2 and releases everything else, mostly nitrogen and oxygen. When the solid material has collected all the CO2 it can, the fans stop running and the device closes.

For the next step, the device needs heat. When the solid material reaches 100° Celsius (212° Fahrenheit), it releases the stored CO2. The same solids can then be reused to grab more CO2. Figuring out how to provide that heat was one of the project’s biggest challenges, Ishaq says.

The electricity made by wind turbines would power the devices’ fans. It also could power the equipment, such as an electric boiler or heat pump, to heat the carbon-collecting solid. In the new work, the team proposed a third option: storing some of the H2 made by the electrolyzer and burning it later for heat.

To store the CO2 released from the material, Ishaq’s team proposes injecting it into a type of deep-sea rock known as basalt. That rock reacts with the gas, turning it into more rock in 10 to 25 years.

What’s next?

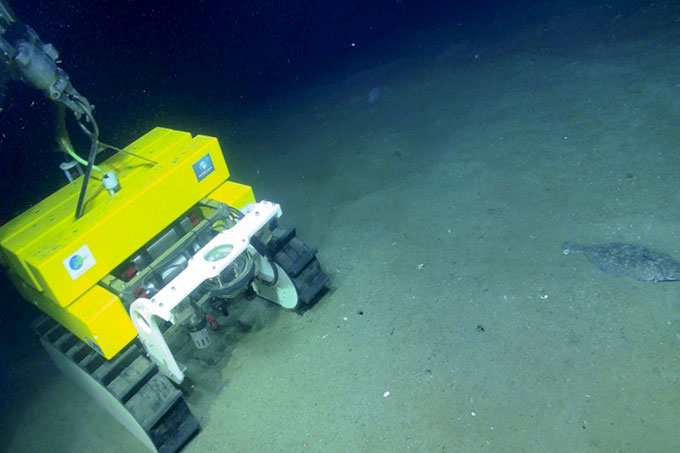

The new study is part of a larger project called Solid Carbon. In other parts of that project, underwater robots monitor what happens to the CO2 stored in basalt. Researchers want to make sure that the carbon won’t go back into the atmosphere or cause other problems. Scientists elsewhere are also working on turning CO2 into stone to help fight climate change.

Ishaq’s team modeled wind turbines, electrolyzers and DAC units on computers to confirm their proposed system is a good idea. The next step is to test a small version of this setup on a floating platform in the ocean.

Large-scale testing is too expensive for now. But Ishaq thinks that the cost of offshore wind farms and DAC will fall, just as the price of solar panels has over the past 20 years. Experts predict that, by 2050, wind farms may cost half of what they do today, he says. But it’s hard to predict the future cost of new technologies, such as DAC.

Rocking the seafloor

In the Solid Carbon project, researchers are investigating how carbon dioxide captured at the ocean’s surface reacts with rocks on the seafloor. They use a deep-sea crawler named Wally to study this process. The goal is to capture carbon in a way that keeps it from escaping into the atmosphere.

Zaaijer is intrigued by the combination of the three pieces. This would allow for an almost continuous supply of energy from wind. It also provides a way to bottle that energy up until it is needed. This system has two ways of converting energy — electrolysis and DAC. Overall, he says, “The system provides a lot of flexibility and helps balance supply and demand, but at a high cost.”

A few things should happen before people invest in bonus tasks for offshore wind farms, says Greg Mutch. A chemical engineer, Mutch studies DAC tech at Newcastle University in England. He says setting priorities is key for reaching net-zero greenhouse gas emissions.

The top priority should be getting more renewable electricity into the power grid and more electric vehicles onto roads, Mutch says. Next, industries that cannot avoid producing CO2 should capture that gas onsite for underground storage. (Those industries include steel- and cement-making factories.) Finally, DAC tech can help get CO2 out of the air and into rocks.

But combining all that tech with wind farms or other systems, he says, “will only make sense in a world that already has plenty of clean energy.”