A Spider’s Silky Strength

What makes spider webs so strong? Scientists attempt to unravel the secrets of silk.

Share this:

- Share via email (Opens in new window) Email

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Share to Google Classroom (Opens in new window) Google Classroom

- Click to print (Opens in new window) Print

By Emily Sohn

Legend has it that a Chinese princess discovered silk while drinking tea under a mulberry tree. A silkworm cocoon fell into her cup, and when she grabbed the bundle, it unwound into a single strand of silk. For thousands of years, the Chinese kept the process of making this beautiful fabric a secret.

|

|

Silk threads can be dyed bright colors and then woven into beautiful fabric. |

| iStockphoto |

Since then, researchers have unraveled many of silk’s mysteries, but they still don’t fully understand how silkworms, spiders, and other small creatures create what turns out to be one of the toughest materials known.

|

|

Silkworms weave silk into white cocoons. |

| iStockphoto |

But Ann Terry, a physicist and a visiting professor at Oxford University in England, thinks that she and other researchers are closing in on that remaining mystery. Terry and other experts hope that current research into silk will lead to a new generation of fabrics that are lightweight and superstrong. Such materials would be useful for medical and military purposes and also could help astronauts and clothing-makers.

Strong stuff

The silk industry still depends on silkworm silk, but scientists have lately focused their attention on spider silk because it’s much tougher. (Toughness describes how much energy it takes to break a material.)

|

|

Spiders use a particularly tough type of silk to form the “arms” of their webs. These arms, like spokes of a wheel, run outward from the center of the web, where the spider in this photo is. |

| iStockphoto |

Spiders can spin different types of silk, some of which are tougher than others. In a classic orb web (like the kind you’d expect to see in a haunted house), the toughest type of silk forms the arms of the frame. These arms, like spokes of a wheel, stretch outward from the center of the web, says Gareth McKinley, a scientist at the Massachusetts Institute of Technology in Cambridge. Another type of silk, which is sticker, forms the spirals that connect the arms of the frame. This sticky silk helps the spider capture its prey.

Spider silk can be “strong stuff,” McKinley says. To test silk’s strength, scientists hang weights from the frame threads of an orb web, then measure how much weight those threads can hold. The researchers have found that spider silk can be as much as 100 times tougher than the same amount of steel. It is about twice as tough as Kevlar, a synthetic fiber used to make sturdy objects such as bulletproof vests and boats.

Slippery and sticky silk

Spider silk starts out as a goopy, yellowish liquid inside the animal’s body. So, how do silk-spinning creatures turn this liquid into one of nature’s toughest solids?

To better understand how that happens, McKinley and colleagues tested two properties of spider silk: slipperiness and stickiness. To test slipperiness, they used a microscopic device that mimicked the motion of a thumb and forefinger sliding back and forth against each other, with a glob of liquid in between. The stickiness test mimicked a thumb and forefinger pulling a glob apart over and over again.

|

|

Shawna Liff, a graduate student at the Massachusetts Institute of Technology, works with a synthetic material that is similar to spider silk in its strength and stretchiness. |

| Donna Coveney/MIT |

Sliding the glob quickly, the researchers found, made spider silk 30 times as slippery as it was to start with. And pulling made it more than 100 times as sticky.

Those results help explain what happens when a spider squeezes out liquid silk through the narrow channel in its abdomen. First, the silk becomes slippery. This allows the silk to flow more easily as the spider excretes it. It’s so sticky that the spider can hang from it—like a person dangling from a bungee cord. When clinging to a strand of silk, a spider can change how fast it drops by varying how quickly it draws out its silk, McKinley says.

|

|

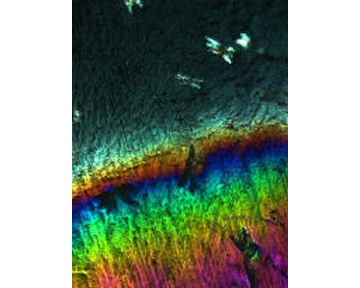

This microscopic picture shows what happens when a synthetic material that’s like silk gets stretched. The stretched part of the material is near the bottom of this picture. It appears to be brightly colored because the molecules are lined up. |

| Courtesy of Gareth McKinley Lab/MIT |

Scientists have already figured out how to extract liquid silk from a spider’s body and to use it to spin fibers. But these human-made threads are never as tough as the ones spiders spin on their own, Terry says. Scientists are still trying to figure out exactly why. They’ve found out, for example, that the protein molecules that make up the silk line up and form parallel chemical bonds inside a spider’s body. This adds an extra measure of toughness, Terry says. Spiders regulate the amount of water and other molecules that go into their silk supplies, which can also affect the silk’s quality.

Supersilk soon?

Unfortunately, farming spiders for their silk is impractical because the creatures produce only very small amounts of liquid. They are also too territorial to tolerate living closely with other spiders. Silkworms are easier to breed and keep in captivity.

The spinning process that silkworms use may explain why their silk isn’t as tough as spider silk. Unlike spiders, which draw silk out of their abdomens, silkworms draw silk out of their mouths. They move their heads in a figure-eight pattern as they do this. In a recent study in which researchers kept the worms’ heads from moving, the worms produced fibers that were just as tough as spider threads.

This finding suggests that silk manufacturers might someday be able to use the silk from silkworms to make spider-strength thread.

Researchers are also looking for more efficient ways to make silk. Some experiments have involved inserting the spider’s silk-making gene into alfalfa, goats, and other organisms to have them produce silk proteins. These proteins could then be harvested and spun into silk.

Ultimately, understanding the biology of the silk-making process and the physical qualities of silk should help researchers make even better materials, Terry says. Knowing how each factor affects the final product will give scientists more control over the process. And that control could open a wealth of potential uses for silk—from the manufacture of lighter, stronger protective gear to the ability to help repair torn ligaments in people.

Spiders make silk spinning look easy, but they’ve had millions of years to figure it out.

“Nature still beats us,” Terry says. “We have a lot to learn from nature.”

Going Deeper: