Sound ways — literally — to move and filter things

The tiny force of a sound wave can get some impressive work done

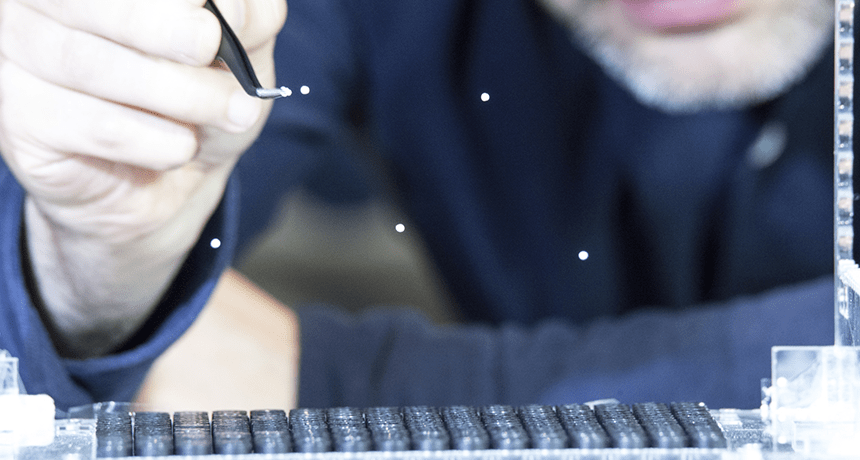

Asier Marzo uses the force of sound to keep multiple plastic beads (white dots) floating in the air.

Asier Marzo

Share this:

- Share via email (Opens in new window) Email

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Share to Google Classroom (Opens in new window) Google Classroom

- Click to print (Opens in new window) Print

By Dan Garisto

If you enjoy listening to a song, you might say it moves you. Of course, you don’t mean that the sound pushes you around. But with new techniques, some scientists have begun using sound to physically move objects.

You can start to imagine how this works if you’ve ever been near a big speaker at a concert. As it blasts low notes, you might feel them as vibrations. Indeed, sounds are vibrations that travel through a substance, such as air or water. You hear a sound when vibrations move your eardrum.

These vibrations, or sound waves, carry a tiny amount of force. Although the force of sound is weak, it can move small objects when used in just the right way. Scientists call this acoustophoresis (Ah-KOO-stoh-for-EE-sis). The word comes from the Greek acousto, meaning “to hear,” and phoresis, meaning “migration.”

“In the end, it’s just moving with sound,” explains biomedical engineer Anke Urbansky. She works at Lund University in Sweden.

Urbansky is among researchers who today are using the force of sound in a variety of clever ways. These range from from 2-D and 3-D printing to analyzing blood to purifying water. Some of them even use sound to make small objects defy gravity.

Collision course

It may seem strange, but the trick to manipulating objects with sound is creating places that have no sound. Even odder is how scientists create this silence in the lab: by colliding sound waves.

Sound waves have a height, or amplitude (AM-plih-tuud). The bigger their amplitude, the louder the sound. Wavelength is another measure of sound waves. It’s the distance from the crest, or top, of one wave to another. High-pitched sounds, such as a whistle, have short wavelengths. The low-pitched sounds that a tuba makes have longer wavelengths. (Levitating objects with sound is a seemingly quiet affair. The sound’s short wavelength makes it too high-pitched for humans to hear).

When sound waves crash into one another, they can combine in different ways. How they combine affects the new wave’s amplitude and wavelength. Where the crests of the waves line up, they combine to make an even taller crest. The sound there is louder. But if a crest lines up with the bottom of a wave — its trough (Trawf) — they combine to make a smaller crest. This quiets the sound.

When the crest of a wave lines up perfectly with the trough of another wave, the two waves cancel each other out. At that spot, the amplitude is zero, so there is no sound. Points along a sound wave where the amplitude is always zero are called nodes.

In the early 1930s, scientists discovered they could use nodes to levitate objects. Two German physicists, Karl Bücks and Hans Müller, placed droplets of alcohol at nodes they had created in their lab. Those droplets hovered in the air.

This will happen because the force of sound pushes objects from loud areas to quieter ones. This traps the objects in nodes where it’s quiet, explains engineer Asier Marzo. He builds acoustic levitators at the Public University of Navarre in Spain.

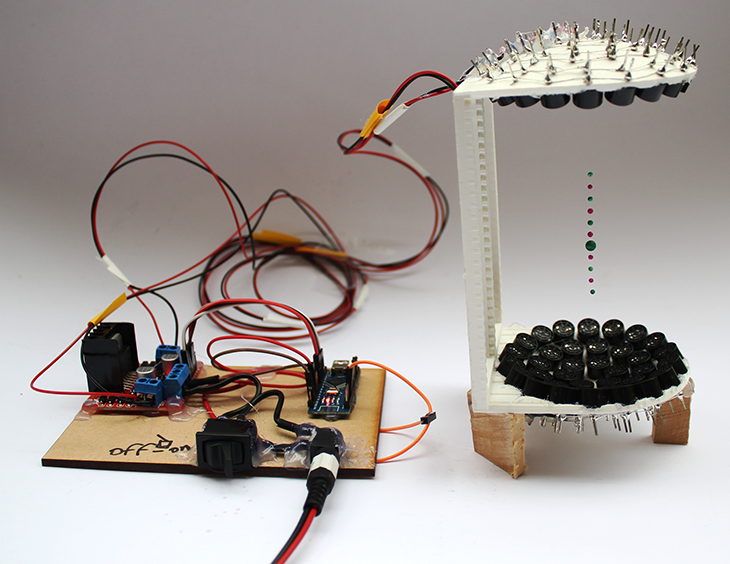

One of Marzo’s projects involved hundreds of tiny speakers. By using so many, he can move and levitate up to 25 small objects at once. How small? Each was a millimeter (0.03 inch) wide. Marzo and his colleagues have even created a kit that lets people build their own acoustic levitator at home.

Other scientists are finding even more practical uses for moving objects with sound.

In the blood

At Lund University, Anke Urbanksy is part of a team that uses sound to move white blood cells.

These cells are part of the immune system. They show up in large numbers to fight off germs. Counting the cells is a good way to tell if someone is sick. The more white blood cells someone has, the more likely they are to have an infection.

“The problem is if you have a normal blood sample, you have billions of red blood cells,” Urbansky says. Finding the few white blood cells in the mix is like finding a needle in a haystack.

The trick is to isolate the cells. Normally, scientists use a centrifuge. This machine rapidly spins blood samples until white blood cells separate from red ones. White and red blood cells part ways because they have different densities. But separating blood with a centrifuge takes time. It also requires at least several drops of blood.

Urbansky’s goal is to separate very small amounts of blood — just five microliters per minute — with sound. (One microliter is about one-fiftieth the size of a water droplet.) To do this, she uses a silicon chip “about the size of a Kit-Kat [candy bar],” she says.

This chip sits on top of a tiny speaker, which provides the sound. When red blood cells run through the chip, sound from the speaker ushers them down the middle. White blood cells are less affected by the sound. Having a different size and density, they stay along the sides. This process separates the blood.

“Just by having a difference in how much force is acting on them … we can separate them,” Urbansky explains.

The technique is useful only for separating small amounts of blood. At its pace, it would take a chip more than four months to sort a liter of blood! Luckily, some possible uses, like counting white blood cells, require only a drop or two.

The technique is still a ways off from being used outside of the lab. For now, Urbansky is working on connecting the chip to a machine that would count white blood cells.

Like oil and water

Separating oil from water is another potential use for this technology. Despite the age-old saying, oil and water do mix. In fact, it’s hard to completely separate them. Bart Lipkens is part of a team that has taken up the challenge. This mechanical engineer works at Western New England University in Springfield, Mass.

Drilling for oil and extracting it from the ground uses a lot of water — and leaves that water tainted with oil. The oil industry creates 2.4 billion gallons of such oily water each day in the United States. That’s more than twice the amount of water used daily by the nearly 9 million people living in New York City.

Laws and regulations require oil companies to partially clean up the water. Those companies use a type of centrifuge that spins the water until oil and dirt separate out. But this process doesn’t fully clean the water. It leaves behind particles of oil about the size of bacterial cells. They’re too small for a centrifuge to remove. Some types of oil are toxic. In time, all of those tiny droplets can add up, harming the environments in which they’re dumped.

But Lipkens thinks acoustophoresis can help. His team has created a filter that uses sound to capture and separate tiny oil droplets from water.

First, dirty water flows down an upright pipe. Speakers attached to the pipe create nodes inside. Those nodes stop dissolved oil droplets in their tracks while letting water molecules pass. Being less dense than water, the clumping oil droplets rise to the top of the pipe. An early version of the device filtered oil from thousands of gallons of dirty water in a day.

But oil companies aren’t using the technology yet. Without stronger limits on how much oil is allowed in water, oil companies won’t spend money on such new technologies, Lipkens says.

Fine print

Printers can be finicky. Most work with only specific ink cartridges. But what if you wanted to print with other types of liquid? Engineer Daniele Foresti at Harvard University in Cambridge, Mass., has designed such a versatile device. It uses sound to print just about any liquid, from honey to liquid metal.

Liquids have two traits important for printing: cohesion (Ko-HE-zhun) and viscosity (Vis-KAH-sih-tee). Cohesion is how much the liquid wants to stick to itself. Viscosity is how thick the liquid is.

Most inkjet printers can use only liquids with a certain viscosity. If the ink is too thin, it drips too fast. If it’s too thick, it clumps.

Foresti realized he could use the force of sound to print liquid “inks” with various cohesions and viscosities. He does so by helping gravity. In acoustic levitation, sound fights against gravity by pushing objects up. Foresti uses sound to do the opposite. It adds to gravity’s force, pushing objects down.

Here’s how it works: A droplet forms at the end of a printer’s nozzle. Normally, droplets detach when they grow big enough (picture a water droplet hanging from a faucet). The droplet falls when the force of gravity overcomes the droplet’s cohesion, or what keeps the droplet stuck to the rest of the liquid.

In Foresti’s printer, a speaker sits behind the nozzle. It directs just the right amount of sound downward. Those sound waves push down, which helps gravity make the drop detach. Once detached, the drop shoots down onto the surface to form part of an image. Thicker liquids can even be printed into a 3-D structure.

Using sound to create things we can touch and see may seem strange. But the technique shows a lot of promise. Printers, medical devices and levitating displays are just a few of the potential uses.

For now, devices that use the force of sound to move objects are mostly confined to a few labs. But as these new and emerging techniques mature, some will become more widespread. Soon, you may be hearing a lot more about the activity of sound.

Harvard’s Paulson School of Engineering and Applied Sciences/YouTube