Old clothes soon may be recycled, not trashed

Chemists are developing processes to reuse the raw materials in discarded clothes

Today people claim to “recycle” old or out-of-date clothes as hand-me-downs to be worn by others. This is actually reuse. Some chemists are working, however, to actually recycle the raw materials in our clothes. Those materials later might later find use in totally new products.

HAKINMHAN/iStock/Getty Images

Share this:

- Share via email (Opens in new window) Email

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Share to Google Classroom (Opens in new window) Google Classroom

- Click to print (Opens in new window) Print

We don’t keep our clothes forever. Some we outgrow. Others wear out. And many just go out of style. Fortunately, scientists are exploring ways to bring new life to our cast-offs through a recycling of their raw materials.

Recycling fabrics is actually fairly daunting. But several research teams are taking on the challenge. Driving them are data showing how valuable many resources are that are tied up — or perhaps we should say woven into — old clothes and other fabric-based goods.

Americans discarded some 15.4 million metric tons (17 million U.S. tons) of textiles in 2018. That’s according to the U.S. Environmental Protection Agency, or EPA. Those trashed textiles weighed as much as roughly 8.5 million cars!

The total includes more than just clothes. There’s carpet, upholstery and bedding, too. But the trashed-textile total has skyrocketed with the popularity of fast fashion — low cost and often poorly made clothes that were never designed to be worn for long. Discards of clothes have nearly tripled since 1990. More than eight times as much end up in the trash heap as in 1970, EPA data show.

Most old clothes end up in landfills, where space is already limited. And much of those buried textiles won’t break down for hundreds of years. That’s especially true for fabrics made from plastics, such as polyester.

In terms of the environment, recycling is better. It offers to find new uses for some or all of the materials that went into what we wear.

It’s hard, but can be done

Take polyester. Most fabrics made from it can be recycled. In practice, however, little of it is. Why? The price for new plastic-based fabrics doesn’t include all their environmental costs. So new polyester often costs less to buy than what it takes to recycle this plastic. That puts recycled polyesters and other synthetic fabrics at a disadvantage.

“Even in the best of times, over 90 percent of plastics were never recycled,” says Judith Enck. She’s the founder of Beyond Plastics and teaches at Benington College in Vermont. When plastics are recycled, she notes, they’re rarely reused more than once.

The quality simply goes down each time the plastic is melted, explains Marc Hillmyer. He’s a polymer chemist at the University of Minnesota in Minneapolis. Polymer is a type of chemical used to make most plastics.

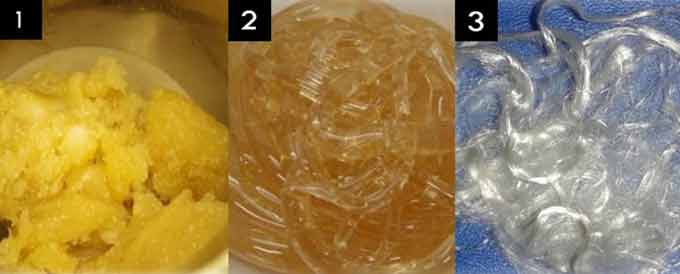

Cotton also is tricky to recycle. This is a plant-derived material made of cellulose. That’s tough to dissolve, notes chemist Herbert Sixta at Aalto University in in Espoo, Finland. But four years ago, his team found a way to use a liquid salt to dissolve shredded cotton.

This created a pulp-like material. It can be turned into fibers about 4 centimeters (1.6 inches) long. Yarn spun from these fibers can be woven or knitted. And the dyed fabric has a higher quality than the original shredded material. Fibers are stronger and hold dyes better, his team finds. They first reported their achievement last year in Green Chemistry.

Unfortunately, cotton is prone to wrinkling. So to reduce wrinkles many manufacturers blend a polymer, such as polyester, with the cotton. These easy-care fabrics now have the soft feel of cotton and its breathability. But processes to recycle each fiber differ.

Sixta’s team decided to work on this, too. First, the team dissolved the cotton. Then they strained the polyester out of the mix. The group described its new technique last year in the journal Waste Management.

Still, challenges remain. “The costs are very high,” Sixta notes. And it takes a lot of liquid solvent. More than 99 percent of these textile blends would have to be recycled to keep costs down and not harm the environment. Another rub: Chemicals in some dyes can limit how well the process works.

So for now, the tons of textile wastes continue to grow. That’s why some experts now argue that the industry and consumers should change their ideas about what people value or look for in fashion. For instance, they might look for fabrics that are durable and tailoring that is timeless. That way, clothes can last longer. And they can more readily be passed along to new users. Indeed, some scientists are suggesting people need to give up fast fashion and choose a new retro trend of less polluting and more durable “slow fashions.”